How does it work?

We at Horizon Testing Inc. utilizes the Zetec MIZ-28 in conjunction with Carbon Steel Inspection (CSI), advanced design probes, remote field amplifier, and software. This inspection consists of a full-length examination performed from the inside of the tubes with equal inner and outer surface discontinuity detection and sizing. An alternating current is applied to an excitation coil which generates a strong electromagnetic field that propagates out of, and extends away from, the exciter along the tube length. The field then re-enters the tube wall axially from the exciter.

The inducer voltage is measured through the use of a detector coil, bobbin, or pancake that is placed in the remote field zone providing for a volumetric inspection with equal sensitivity to ID and OD anomalies of the tube. The sensor coils pick up the disturbance of the field due to the presence of any anomaly caused by corrosion, stress, foreign object, or mechanical vibration. The signal is measured relative to the X-axis in degrees which equates to flaw depth. The technology has the ability to display in a (X-Y) format.

This allows the data analysis to use pattern recognition for characterizing the signals. Typically, the analysis parameters are established where the phase or angular relationship of the signal is measured relative to the X-axis in degrees, which equates to flaw depth.

What Components and Materials are best suited for Remote Field Testing?

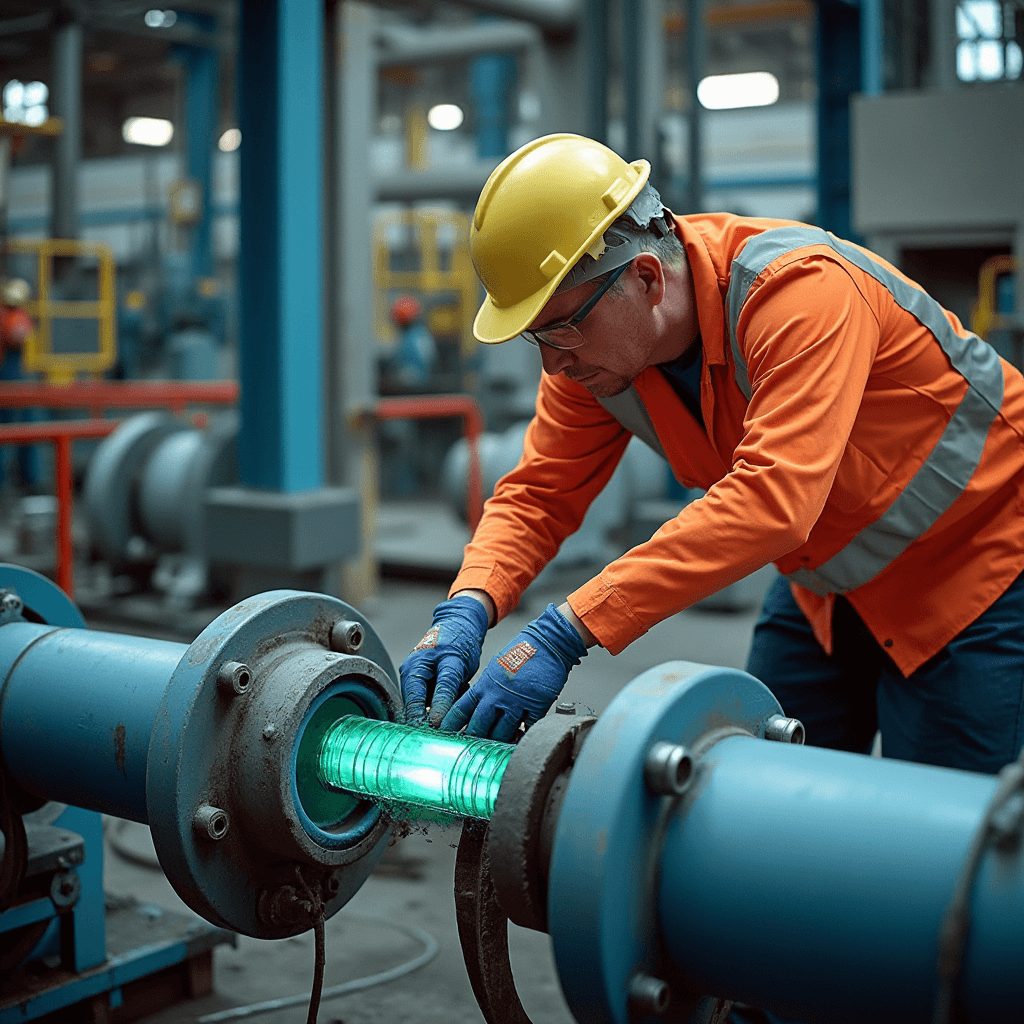

The remote field phenomenon is an electromagnetic testing technique used primarily for in-service, baseline, or QC inspection of ferromagnetic tubing and piping.

Why choose Horizon for Remote Field Testing?

Horizon offers certified expertise, advanced technology, and tailored solutions to ensure precise and efficient Remote Field Testing. Our team is committed to delivering reliable results that meet or exceed industry standards, ensuring the safety and performance of your assets.

How often should Remote Field Testing be performed?

The frequency of Remote Field Testing depends on the specific application and industry requirements. Regular inspections are recommended for critical components to ensure ongoing safety, reliability, and compliance. Our team can help you develop a customized inspection schedule based on your needs.